Dust Collection

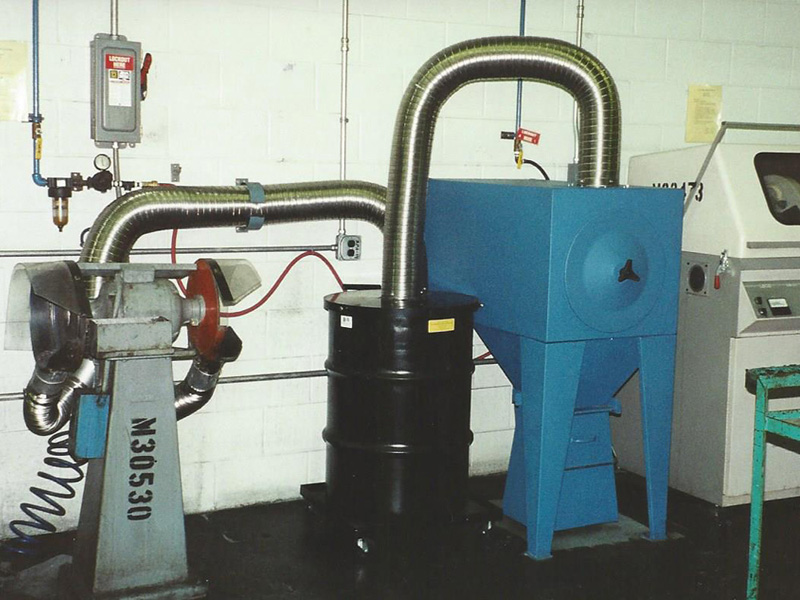

- 1. Pedestal Grinder

- 2. Portable Food Sifter

- 3. Surface Grinders

- 4. Body Shop

- 5. Body Shop

- 6. Printing Press Odors & Dust

- 7. Cast Iron and Silica Dust

- 8. Automatic Grinder - Heavy Sparks

- 9. Batch Mixing

- 10. Baghouse

- 11. Cut-Off Saw

- 12. Cut-Off Saw

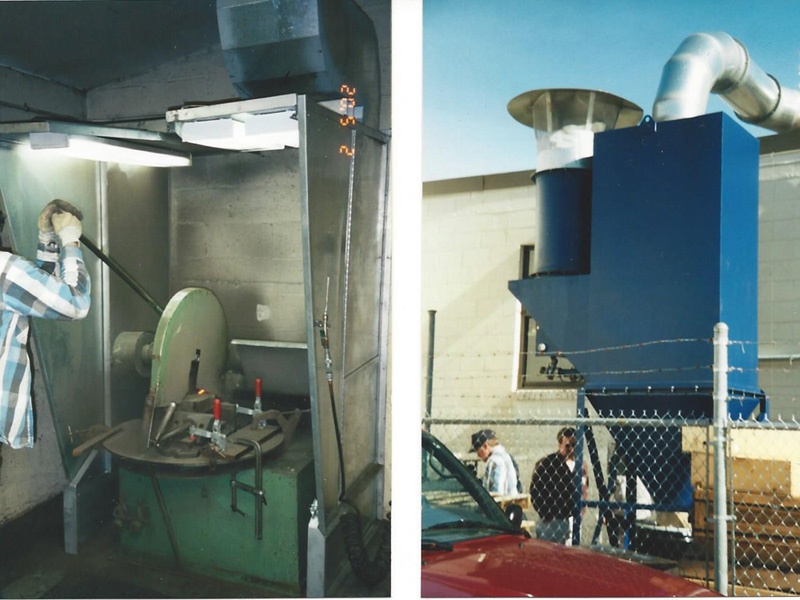

- 13. Abrasive Cut-Off Saw

- 14. Hexavalent Chromium Downdraft Table

- 15. Dust Control Booth

- 16. Composite Dust

- 17. Fiberglass Dust Booth

- 18. Grinding Dust Booth

- 19. Sanding and Grinding Booth

- 20. Belt Sander

- 21. Steel Dust

- 22. Rock Dust

- 23. Borax Powder

- 24. Food Processing

- 25. Spice Dust

- 26. Pharmaceutical Dust Collection

- 27. Food Processing - Stainless Steel

- 28. Pharmaceutical Blending

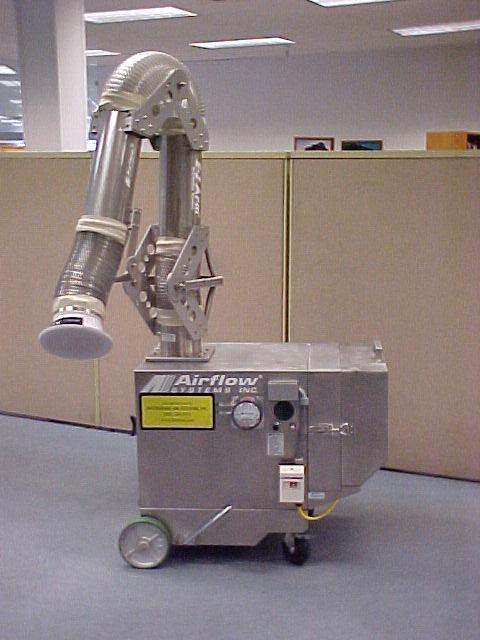

- 29. Stainless Steel Portable

- 30. Band Saws

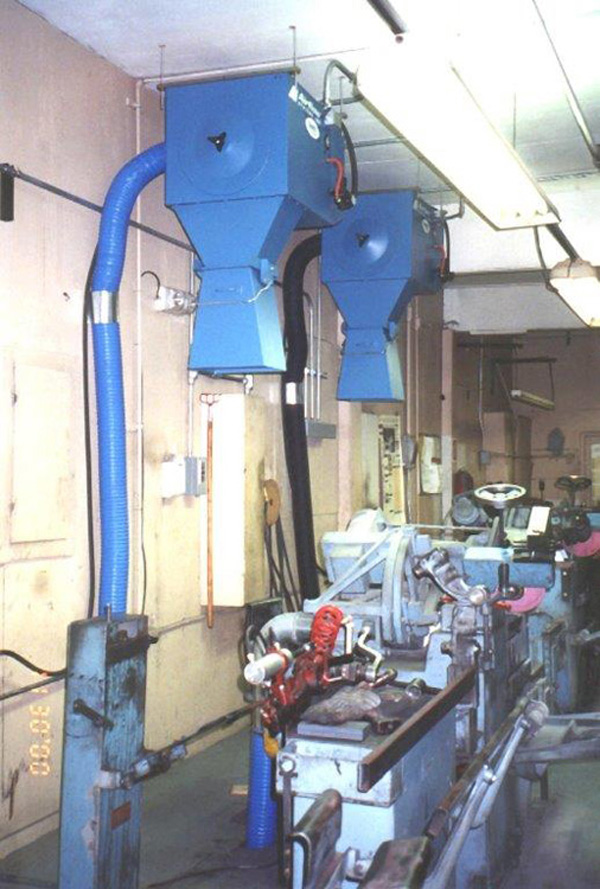

- 31. ID/OD Grinding

- 32. Brazing Copper

- 33. Grinding Dust - Heavy Sparks

- 34. Custom Table

- 35. Abrasive Blasting - Plastic Media

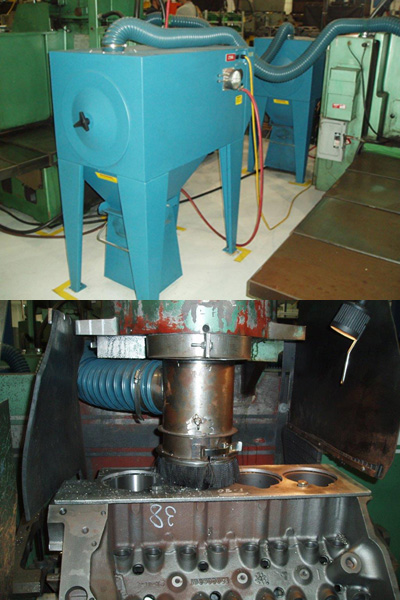

- 36. Grinding on Engine Blocks

- 37. Grinding Dust

- 38. Grinding Dust

- 39. Surface Grinding

- 40. Dual Downdraft Table

- 41. Rottler Boring Machine

- 42. Plaster Dust

- 43. Aluminum Dust

- 44. Stainless Steel Grinding

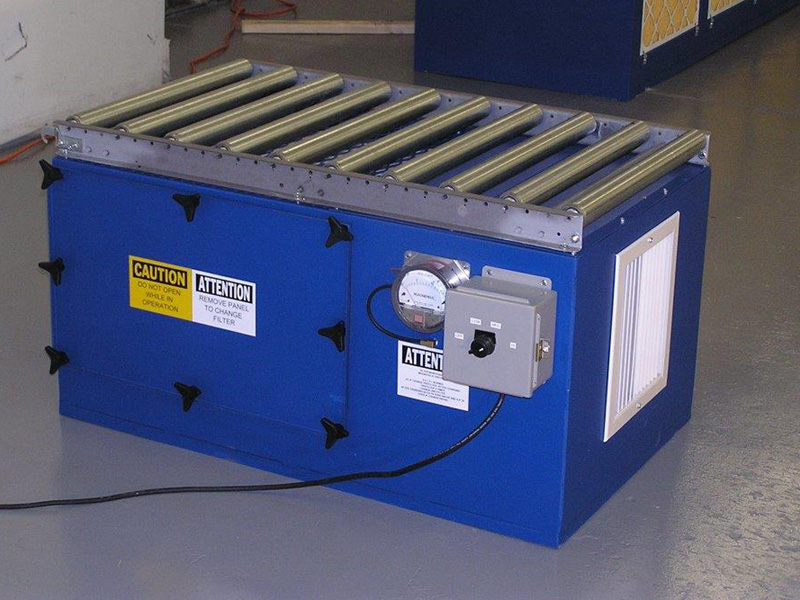

- 45. Conveyor Downdraft Dust Collector

- 46. Graphite Dust

- 47. Hand Grinding