Dust Collection

Industrial Vacuum

Machine Mist/Smoke

- 1. Wet Grinding

- 2. Surface Grinder

- 3. Surface Grinding

- 4. Surface and OD Grinders

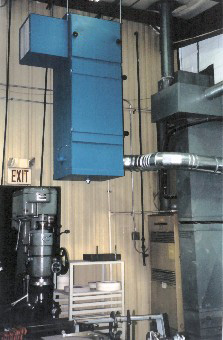

- 5. Machine Shop - Unducted System

- 6. Automotive Stamping

- 7. Stamping

- 8. Cold Forging

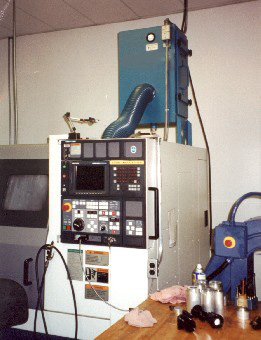

- 9. CNC Mist Collection

- 10. Willemin Machining Centers

- 11. Grinders

- 12. HAAS CNC

- 13. HAAS CNC

- 14. Mazak CNC

- 15. Phoenix CNC

- 16. EDM

- 17. Toyoda CNC

- 18. Grinding Steel

- 19. Machining Centers

- 20. CNCs

- 21. Hardinge CNC

- 22. Screw Machines

- 23. Olympia CNC

- 24. Blanchard Surface Grinder

- 25. Mori Seiki CNC Mist Collectors

- 26. Mori Seiki Mist and Smoke Collector

- 27. Thread Grinder Mist Collector

- 28. Bardons & Oliver CNC Mist Collector

- 29. Davenport CNC