Dust Collection

Industrial Vacuum

Machine Mist/Smoke

Fumes

Smoke Collection

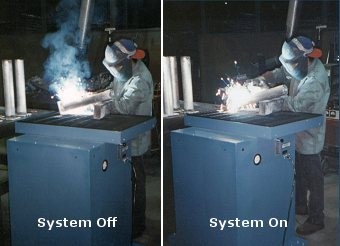

- 1. Welding Smoke - Unducted System

- 2. Mig Welding - Unducted Air Cleaning System

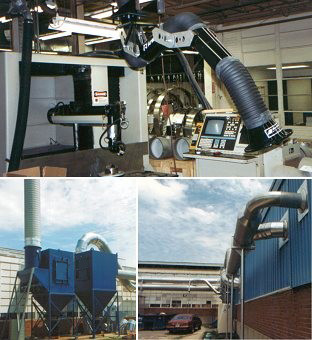

- 3. Unducted System

- 4. Maintenance Welding

- 5. Aluminum Welding - Downdraft Table

- 6. Mig Welding

- 7. Robotic Welding

- 8. Welding Smoke Extractor Gun

- 9. Welding Booth

- 10. Telescoping Arms

- 11. Boom Arm

- 12. Boom Extractor Arm

- 13. Vocational Welding Booths

- 14. Overhead Collector with Arms

- 15. Welding Cells

- 16. Galavanized Welding Fumes

- 17. Welding Smoke Extraction Arm

- 18. Stainless Steel Welding - Portable

- 19. Plasma Cutting

- 20. Welding Shop

- 21. Laser Cutting

- 22. Brazing

- 23. Cutting Slag

- 24. Scrap Yard

- 25. Resistance Welding

- 26. Soldering Fumes

- 27. Welding & Grinding

- 28. Robotic Welding Cells

- 29. Robotic Cell

- 30. Plasma & Build Up Welding

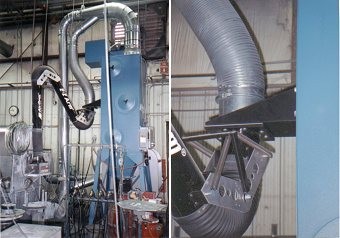

- 31. Arms

- 32. Plasma Torch

- 33. Robotic Cell

- 34. Robotic Cell

- 35. Robotic Cells

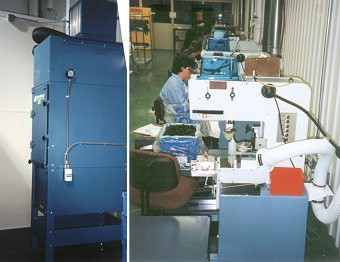

- 36. Soldering

- 37. Soldering

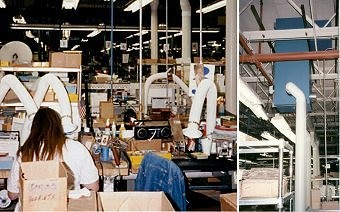

- 38. Glue Pot

- 39. Laser Cutting Table

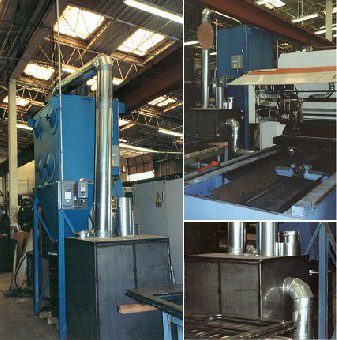

- 40. EDM Smoke - Source Capture

- 41. Air Arcing

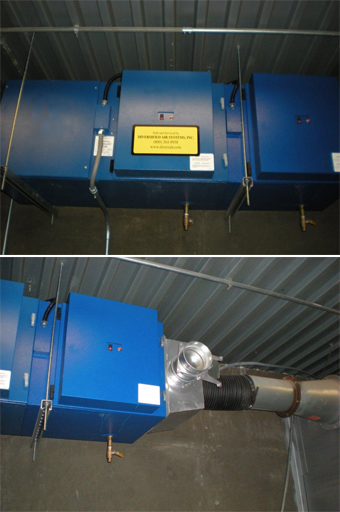

- 42. Vacuum Pumps

- 43. Aluminum Crucible Process

- 44. Laser Welding

- 45. Portable Cartridge Collector for Mig Welding

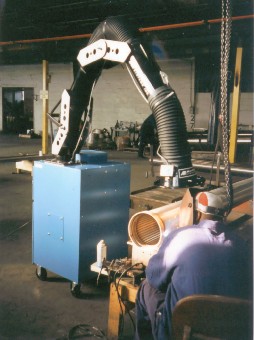

- 46. Boom Arms

- 47. Cooking Vent

- 48. Arc Gouging

- 49. Fume Arm Welding